Managing expiry of products so that customer doesn’t buy them is difficult for one store. The problem gets multiplied when we have to manage 200 remote locations. Its becomes herculean when stores are unmanned. Read to deep dive how we managed them.

Crisis due to repeated expiry instances

It was early days of Daalchini Technologies. I had just returned from inspecting one of the vending machines in Sector 1 Noida. I requested pantry boy to bring a cup of tea and started checking the mail. While I was about to reply to a mail, I saw Ambuj standing in front of me. He looked worried. I asked What happened, and the reply was – again one customer has received the expired product. In the same breath, he almost shouted, till when we will be vending expired products to our customers. He did not wait for my reply, banged the door and left the room. I echoed with his sentiments. His anger was justified.

Ambuj used to manage our customer service team. He had repeatedly received the ire of customers for this expiry issues. We had been marred by multiple instances where our vending machine vended products which were beyond use by date.

Operations team were sensitised. Delivery boys were asked to check the expiry of all products of the machine daily. FIFO (First In First Out) and later FXFO (First Expiry First Out) were already implemented for inventory in the warehouse by Hub managers. But Still, issues were not coming under control.

Yet another team meeting for managing expiry

I decided to take the issues seriously. Called Jacob, Nirmal and Joy (our core operations team). The team was clueless. They were doing everything possible to control these rising cases. We again discussed the same implementation of FIFO, FXFO etc but no new idea came up. Finally, Joy told- Sir Don’t worry, from tomorrow it will not happen. He left the room.

Before joining Daalchini, Joy had worked in collections for 2-3 years. He had a very commanding voice. He always believed that if we intimidate the Delivery boys, they will do whatever is expected. Now I could hear his voice – Kal se kisi Machine mein koi expired product nahi Milna Chhyea. Agar mila to wo delivery boy responsible hoga. [From tomorrow none of the machines should have expired products. If any expired products are found, we will that delivery boy responsible]. Post that there was pin-drop silence in the warehouse. I murmured, this is not the way to handle this. Won’t work.

I started doing some research on expiry management. Got a lot of links but none of them had the solution. Generally, the product has a barcode, batch no and expiry date.

Observation on barcode and expiry date

- Barcode of similar product type is the same ( Not always) with different manufacturing date and expiry date

- The expiry date is not stored in the bar code, rather tracked using Lot number through the database.

- In shops, the expiry of stored products doesn’t reach before the products are exhausted.

In other words, Barcode doesn’t have information about the expiry date. So barcode technique can just be used for managing the inventory count, not for shelf life expiry management. Batch No is generally associated with best before date. Unlike Barcode which can be scanned and stored in the system, Batch No needs to be typed manually. As the number of SKUs increase, it becomes a herculean task to enter them manually and track them physically in the warehouse or store.

Typical way of managing expiry in a store

So the only way to keep track the expiry is by checking the products manually. If a store manager manages 1-2 stores he can implement strictly as he is physically present there. Even if some product gets overlooked during routine expiry check, the cashier can also cross verify while the product is being sold. So chances are relatively less than the customer would end up getting the expired products.

The process remains the same for us as well for warehouse and hub. It also remains almost the same for the vending machine. Delivery boy would have to check the expiry date of all the products manually and remove if they are expiring shortly.

However, as these machines are unmanned there is no one to cross-check the expiry at the time of sale. So entire onus of managing expiry falls under one delivery boy. If he misses then the customer would get that product.

Why RFID cant be used for managing expiry

To understand it more deeply, I called one of my friend who works in the supply chain industry. He told: RFID can also be used for managing expiry but that would be expensive. An RFID passive Label printer costs approximately 60,000 INR and the cost of printing one RDIF label to track a product costs 40-100 paise (Approximately). Each tag can contain product information such as the expiry date, object pressure, temperature, prices etc. In addition to expiry, RFID can also help

- Checking the availability of stock on shelves

- Identifying misplaced stock on shelves

- Identifying counterfeit products

- Sending updates to the inventory manager

- Support JIT Inventory

- Visibility of inventory throughout the supply Chain

- Perform the inventory functions with less manual intervention

He continued and told that Coca-Cola uses the freestyle machine that utilises RFID technology to identify 30 or more cartridges, determine the quantity of flavouring inside each, and transmit data back to Coca-Cola indicating which drinks are being consumed, and when.

I was completely convinced that RFID techniques are way forward. However, I quickly reminded myself that we are a startup and we have a constraint on the fund. Also, Besides, the method looked expensive for low-value products. It’s not wise to add another 5-10% of the cost of the product on RFID for tracking expiry. It’s not viable.

Concerns raised by delivery boys

Exhausted by a day-long googling and calling people, I decided to call of the day. I could not sleep that night. I was unable to understand why none of the companies has tackled this problem until now? Why have they not come up with a low-cost solution for managing expiry? Have they left for the retailer to solve themselves?

Next day I called some of our experienced delivery boys and asked him why they are unable to manage it. Earlier they were reluctant to share but after getting prompt for Joy, they started sharing the issues

- The placement of the expiry date of the product on the pack is not standardised. Some pack has the expiry details on the cap, some have on the neck and some has on the back of the packets.

- There is no standard way of writing the expiry date. Some have Expiry Date, Some has manufactured Date (associated with shelf life). In case of the manufactured date, Delivery boys have to mentally add shelf life to manufactured date to arrive at the expiry date

- Daalchini Vending Machines has wide varieties of products Like Private Label (Shelf life of few months), Meals (Shelf Life of around 2 days), Quick Bite (Shelf Life of 1 Day), Snacks from nationalised brand and Beverages.

- Moreover, there are 32 different types of products and over 200 units in one machine. So they have to check the expiry for 200 items.

One of the delivery boys quipped, Forget about us sir, even you people will not be able to check the expiry of all products accurately of one machine. We manage 5 machines in a day, sir. Even before I could consume this statement, another delivery boy who rarely used to open up during meeting finally broke his silence and told “Sir ye sab manage kar bhi leta agar Hindi mein Likhar rahta” [Sir we could have managed, had it been written in Hindi?]

I did not have any word but to say Thank you to all. They all went back to their hubs.

There was a strange silence in the room. As usual, Nirmal started planning for the next day. I went back hitting keyword pretending to work. I was unable to concentrate. Could not work.

Eureka Moment – Let’s use colour

While I was about to leave for the day Jacob (one of our senior-most members of the Operations team) came to me and told he wanted to discuss something with you. I felt a ray of hope. I guessed he had found the solution. He told the problem lies in the detection of the products which are getting expired. What if we make the details of the expiry glaring for the products, it will reduce the pain of reading expiry date? Did I say – How? The reply was: By using colours. I instantly connected. It was a eureka moment.

Next day, I came a little early to the office and waited anxiously for Jacob to come. He came in around 11 AM. I could sense from his bobbling eyes that had not slept last night. He opened his laptop and showed me some design he had created overnight. For the first time, I took a deep breath. I felt we are going to win this battle now.

He had selected 5 colours for 5 working days. Using an extra layer of creativity, he had used spoons to differentiate day. 1 spoon for Monday, 2 spoons for Tuesday and so on.

I liked the concept. I was sure this was going to be a game-changer. As they say, Experience is more important than talent sometimes. Jacob with 15 years of experience under his belt, did it again.

While we started planning to roll this out, I got stuck again. I told Jay, we have two different varieties for meals. One has 1-day expiry and other has 2 days expiry. He replied, we will have two different design but in the same colour, keeping his eye fixed on his computer screen. I again asked we have some products expiring at the month-end also, what about that? He did not reply this time. I felt silly at my question and got back to my work.

After some time I received below pattern in the mail from Jacob.

Implementation on ground

Jacob shared the details with the team. Nirmal got that printed and pasted them in all hubs. Hubs manager were communicated of this new colour scheme. Delivery boys were appraised about this. They were really happy with these new ways of managing expiry.

I thought issues are settled. I should move on to the next challenge. And slowly this expiry management issues started getting faded in my mind. However, the team continued working on the same. They kept brainstorming to improve it further.

One day, Nirmal came and shared what they are going to implement next.

- Rounding off shelf life: For Private label Snacks, there would be rounding off expiry date. Expiry date would be either 15th of the month or 30th/31th of the month.

- Minimum shelf life requirement for new stock: They have negotiated with the vendor that the stock must have at least 75% of the shelf life before they enter into our supply chain

- Expiry check to be done once in a month: Expiry check of the nationalised brand will be done just once in the month, during 27-31 of the month.

- Managing reverse logistics of expired product: Any product expiring next month will be removed from the vending machine shelf and brought back to the warehouse during month-end expiry check. After that hub manager will get them sold via fast-moving machines.

By introducing these additional processes, They did not settle after solving the readability problem of expiry date by replacing them with colour but also streamlined the process of PO, receiving and expiry check.

Implementation to next level

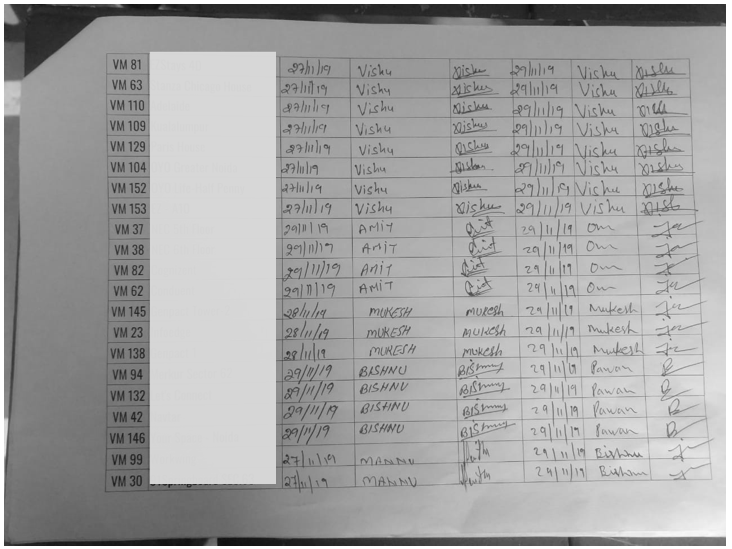

After around 1 week I was casually walking in the hub then I heard Joy repeatedly asking one delivery boy to sign on the paper. I went there and asked what happened? Joy replied – Nirmal Sir ne bola hai jo expiry check karega usko sign Karna parega [Nirmal Sir has told that whoever completes the expiry check he needs to sign] .

I asked delivery boy, why are you not signing? He replied – Sir, main sure nahi soon ki Abhi machine mein koi bhi expired product nahi hai. Main kal check kar ke sign kar dunga. [ I am not sure if there is no expired product in the machine. I will check tomorrow and then sign]. The matter got sorted.

Later these processes were included in the app.

While I was going back to the Operation room, I thank god for people like Nirmal having around, who make the process till the eternity. Even though the team had replaced daily expiry check to monthly expiry check, they made sure that there is no leakage by getting it checked by multiple people. The final nail in the coffin was holding accountability by asking them to sign on a paper. Generally, We sign on paper only if we are 100% sure. It has a psychological effect. Wow.

Conclusion

Detecting and managing the products which have expired in the supply chain is one of the biggest headaches for inventory managers. Even today, there is no frictionless low-cost solution for managing them effectively. Some of Inventory Management Solution partners suggest mapping Barcode and Lot Number.

This solves the problem partially as the system would know some of the products are getting expired but they will not know exactly where. Other solutions like RFID based tracking are really expensive for low-value items. Use of the robot is far-fetching options at this stage, I think.

So in our case, we resorted to the indigenous way of solving this problem. The team followed majorly 5 steps to fix this problem.

- Identification of the problem – Here the problem was not that Delivery Boys were unable to remove the expired product. Rather problem lied in the readability of expiry information. The problem also lied in the warehouse, where short expiring products were present.

- The creative way of solving the problem – Introduction of colour scheme was a novel idea to tackle this problem. It improved the readability of some products. Rounding of expiry date helps them just check manufacturer date. Sourcing of product with more 75% of shelf life eliminated corner cases as well.

- Communicating the solution to the team – Nirmal and team shared these new ways of working with everyone in the team meeting. They also pasted the printed paper which reminded boys of the importance of expiry check now and then. They conducted training sessions to help them find expiry date quickly.

- Implementing the solution religiously – Team also worked on tracking and monitoring of the implementation. Visual inspection of machine from the pic shared by the delivery boy was scrutinised by hub managers and so on.

- Bringing humane aspect into the process – Unlike a typical situation, where we hold delivery boy accountable for their mistake, here team kept the accountability at the end. Rewards were also announced based on performance.

And thanks to the team, post this implementation, we have sold over 1 Million products with six-sigma accuracy. And I also hope Ambuj must be happy now as the entire exercise was started after he banged the door.

However, it is not 100% solved yet. This works well for 250 vending machines across 6 cities. But will it work when we have more than 2000 machines? Or will this process crack as we go? Time will tell.

Small note

People who have worked in an early-stage startup with just 4-5 people in the company, will be able to connect to this article. From the outside, it looks trivial issues but when you are in the system, these trivial issues burn many of your midnight oils.

As they say, the fun lies in building the process not in following them. The startup allows experiencing that building every day. Later on, most of those processes would be replaced by tech, as was done in our case, but the thrill of developing that system can’t be taken by anyone. It was exhilarating to experience.

References

- https://blogs.sap.com/2014/09/08/shelf-life-expiry-management/

- https://datecheckpro.com/2016/07/23/3-problems-in-supermarkets-that-cause-products-to-expire/

- https://datecheckpro.com/2019/09/15/effective-expiration-date-management-process/

- https://brandequity.economictimes.indiatimes.com/news/business-of-brands/retailers-get-cautious-about-expiry-date-of-food-products/47783042

- https://retailblog.yoobic.com/4-reasons-why-every-grocery-retailer-needs-expiration-date-tracking-technology

- https://www.gofrugal.com/blog/pharmacy-expiry-management/

- http://justfooderp.com/blog/6-tools-for-better-shelf-life-management/

- https://www.nicolisproject.com/en/expiration-date-electronic-shelf-labels/

- https://www.shopify.in/retail/inventory-management-crucial-tools-to-keep-your-products-in-check

1 comment

I liked the approach of solving the problem. New learning. Will try this out.

Keep writing on topics like this.

Comments are closed.